Aluminum

Aluminum system

Let the windows wear a sturdy coat.

Self-built aluminum workshop

It covers an area of 10,000m2, which is composed of high-end aluminum processing equipment and two independently developed aluminum spraying lines.

Aluminum system to let the windows wear a sturdy coat

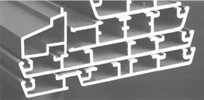

Patented aluminum mold

Sayyas's aluminum profile has a design patent, and its mold and intellectual property rights are exclusively owned by Sayyas.

Patented seamless welding technology for outer aluminum frame

In 2012, Sayyas independently developed the seamless welding technology for outer aluminum frame, and obtained the technology patent, thus accelerating the industry into the era of outer aluminum seamless welding.

The seamless welding for outer aluminum frame makes the product have better water resistance and appearance, and avoids the hidden danger of acid decay and paint removal in rain water.

High-end equipment to ensure accurate cutting and bending of aluminum

Sayyas selects plain aluminum with a wall thickness of 1.5mm (2.0mm for integrated window screening products), and introduces German Elumatec dual-saw cutting aluminum with processing accuracy of 0.1mm. Sayyas has several imported CNC bending machines, which can run back and forth 6-12 times to ensure the accuracy of aluminum bending radian.

German Elumatec dual-saw

Italian 3C bending machine

Swiss PBT bending machine

EMMEGI equipment

JMD CNC sawing center

Laser intelligent equipment cutting machine and hydraulic bending machine

Perfect aluminum color spraying

Sayyas introduced the Swiss Gema spraying system, which has a unique aluminum spraying pretreatment process to effectively ensure the adhesion of the paint. According to different design styles, the color of outer aluminum can be customized to fully meet different needs.

Hanging spraying line for outer aluminum

Hanging automatic spraying line for dual "U" shaped closed loop outer aluminum frame

The entire processing time is about 3.5 hours. It includes automatic spraying pretreatment system, tunnel hot air drying system, electrostatic powder spraying system, and tunnel powder curing system. Automatic spraying pretreatment includes pre-degreasing - degreasing - tap water washing - pure water washing - pure water direct spray washing - chromium-free passivation. Ensure the adhesion of aluminum film.

Tel.

400-6700-999

Address

Address of Shuangcheng factory:

Crossroads of Songhuajiang Road and Xing'an Road, New Industrial Park, Shuangcheng Economic Development Zone, Harbin

Address of Haxi factory:

No. 9, Xinnong Road, Nangang District, Harbin

Address

Address of Nanjing factory:

No. 18, Zhonghuan Road, Jiangning District, Nanjing

Address of Nanjing office building:

Building F, Shimao 52 +, Yuhua District, Nanjing

JD official flagship store

Tmall official flagship store